- Home

- News

- Assets

The SharjahWastewater and Water Reuse Company.

- Bio Products

- Lakes and Wildlife

- Research

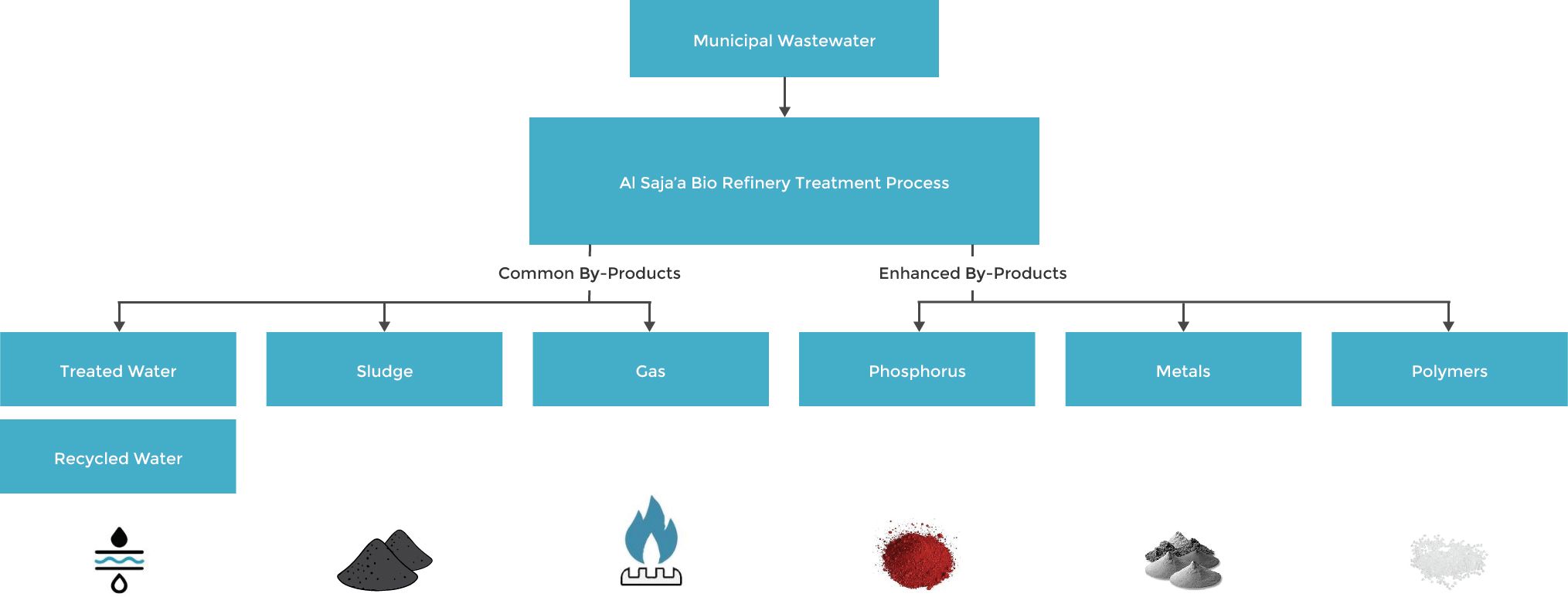

The Wastewater Treatment Process produces different types of By-Products with some of them considered as waste and disposed. Common ones are the Treated Water, Sludge and Gas. These By-Products can further be enhanced to become products on their own (Treated Water, Recycled Water, Sludge, Gas, Metals, Polymers).

New technologies are progressively developed worldwide to harvest other valuable materials or chemical elements like metals or phosphorus out of wastewater.

The concept of Bio-Refinery takes all its sense here, Qatra called them Bio Products.

The Al Saja’a Bio Refinery main purpose is to clean the Municipal Wastewater in order to release a clean water safe for the environment and public health. In this process, 99% of the volume of the Influent becomes clean Treated Water. This Treated Water is today mainly reused for irrigation and landscaping where it excels to grow plants thanks to its rich content in essential nutrients.

This Treated Water can further be cleaned with advanced technology to produce a water meeting the Potable Drinking Standards (See Recycled Water below or the Recycling Plant Asset for more details). As such, in a region where water is scarce, the Treated Water is an essential resource.

This Lab Test shows the typical results for the composition of the Al Saja’a Bio Refinery Treated Water. Some parameters vary day-to-day depending on the composition of the incoming Municipal Wastewater

The Al Saja’a Bio Refinery main purpose is to clean the Municipal Wastewater in order to release a clean water safe for the environment and public health. In this process, 99% of the volume of the Influent becomes clean Treated Water. This Treated Water is today mainly reused for irrigation and landscaping where it excels to grow plants thanks to its rich content in essential nutrients.

This Treated Water can further be cleaned with advanced technology to produce a water meeting the Potable Drinking Standards (See Recycled Water below or the Recycling Plant Asset for more details). As such, in a region where water is scarce, the Treated Water is an essential resource.

This Lab Test shows the typical results for the composition of the Al Saja’a Bio Refinery Treated Water. Some parameters vary day-to-day depending on the composition of the incoming Municipal Wastewater

The Treated Water produced by Qatra is perfectly suitable for irrigation and landscaping or dust control. However, for more stringent requirements like the ones requiring a low salinity or zero pathogens, additional treatment is compulsory.

Qatra produce and sell different Recycled Water qualities such as Reverse Osmosis Water or Demineralized Water. The former can be used in a wide array of industrial applications (district cooling, concrete batching plant) and non-drinking applications while the former is a very specific water used for boilers or any other industrial requiring a salinity close to zero.

In parallel, Qatra is conducting a research in Partnership with the University of Sharjah and the Sharjah Research Academy Aquifer Storage and Recovery as a mean to make Recycled Water potable (See Research Section).

Recycled Water is the most sustainable water available as it consumes 4 times less energy compared to desalinated water and is also an alternative to unstainable aquifer abstraction. In a region facing increasing water scarcity, Recycled Water is one solution to reach safety in Water Supply.

The Treated Water produced by Qatra is perfectly suitable for irrigation and landscaping or dust control. However, for more stringent requirements like the ones requiring a low salinity or zero pathogens, additional treatment is compulsory.

Qatra produce and sell different Recycled Water qualities such as Reverse Osmosis Water or Demineralized Water. The former can be used in a wide array of industrial applications (district cooling, concrete batching plant) and non-drinking applications while the former is a very specific water used for boilers or any other industrial requiring a salinity close to zero.

In parallel, Qatra is conducting a research in Partnership with the University of Sharjah and the Sharjah Research Academy Aquifer Storage and Recovery as a mean to make Recycled Water potable (See Research Section).

Recycled Water is the most sustainable water available as it consumes 4 times less energy compared to desalinated water and is also an alternative to unstainable aquifer abstraction. In a region facing increasing water scarcity, Recycled Water is one solution to reach safety in Water Supply.

The sludge is the “dirt” removed from the Wastewater and is the main By-Product to dispose. When exiting the process from the Sludge Treatment Building (See page of Bio Refinery Asset), each Kilogram of sludge contains more than 80% of water. This water makes the sludge voluminous and heavy. Every day, the Al Saja’a Bio Refinery generates around 45 tons of this wet sludge.

Till end of 2018, similarly to many wastewater treatment plants in the UAE, Qatra was disposing this sludge to the landfill. This unsustainable approach has changed since beginning of 2019 with the construction of Solar Drying Beds. This energy-efficient solution leverages the sun heat to remove up to 80% of water and subsequently decreasing the quantity to less than 10 tons/day.

This dry sludge is not only a great fertilizer thanks to its nutriment content, but also carries a high caloric value of more than 14 MJ/Kg, making it perfect for Cement Factories as a subsite of Charcoal. In 2019, Sharjah Cement Factories and Qatra signed a Reuse Agreement so the Factory reuses Qatra Dry Sludge.

This Lab Test shows the typical results for the composition of the Al Saja’a Bio Refinery Sludge. Some parameters vary day-to-day depending on the composition of the incoming Municipal Wastewater.

The sludge is the “dirt” removed from the Wastewater and is the main By-Product to dispose. When exiting the process from the Sludge Treatment Building (See page of Bio Refinery Asset), each Kilogram of sludge contains more than 80% of water. This water makes the sludge voluminous and heavy. Every day, the Al Saja’a Bio Refinery generates around 45 tons of this wet sludge.

Till end of 2018, similarly to many wastewater treatment plants in the UAE, Qatra was disposing this sludge to the landfill. This unsustainable approach has changed since beginning of 2019 with the construction of Solar Drying Beds. This energy-efficient solution leverages the sun heat to remove up to 80% of water and subsequently decreasing the quantity to less than 10 tons/day.

This dry sludge is not only a great fertilizer thanks to its nutriment content, but also carries a high caloric value of more than 14 MJ/Kg, making it perfect for Cement Factories as a subsite of Charcoal. In 2019, Sharjah Cement Factories and Qatra signed a Reuse Agreement so the Factory reuses Qatra Dry Sludge.

This Lab Test shows the typical results for the composition of the Al Saja’a Bio Refinery Sludge. Some parameters vary day-to-day depending on the composition of the incoming Municipal Wastewater.

The Treatment Process generates flammable gas (Methane) that can be reused for generating heat or power. Such gas is called biogas. Collecting this biogas for power generator and heat generation requires a minimal capacity to be technically feasible. Qatra will investigate in the coming future the opportunity to do so.

The Treatment Process generates flammable gas (Methane) that can be reused for generating heat or power. Such gas is called biogas. Collecting this biogas for power generator and heat generation requires a minimal capacity to be technically feasible. Qatra will investigate in the coming future the opportunity to do so.

Each cubic meter of Wastewater contains small quantities of a variety of metals like Nickel, Zinc or Copper. With the large amount of volume received daily, several kilograms of metals can be harvested from the Wastewater and Sludge.

Development of technologies capable to extract the metals are driven by more and more stringent regulations and the rarefaction of certain metals from conventional mining. Qatra is monitoring emerging solutions with the objective to adopt such capability in the coming future.

Each cubic meter of Wastewater contains small quantities of a variety of metals like Nickel, Zinc or Copper. With the large amount of volume received daily, several kilograms of metals can be harvested from the Wastewater and Sludge.

Development of technologies capable to extract the metals are driven by more and more stringent regulations and the rarefaction of certain metals from conventional mining. Qatra is monitoring emerging solutions with the objective to adopt such capability in the coming future.

Phosphorus is an essential part of life but also enters in the composition of different products like fertilizers and metals or in chemistry. Phosphorus is extracted from mines. With the increasing demand worldwide and the finite supply, the recovery will become a new viable option.

Several technologies exist and Qatra is exploring when and what could be implemented in the future to harvest this resource from the Al Saja’a Bio Refinery.

Phosphorus is an essential part of life but also enters in the composition of different products like fertilizers and metals or in chemistry. Phosphorus is extracted from mines. With the increasing demand worldwide and the finite supply, the recovery will become a new viable option.

Several technologies exist and Qatra is exploring when and what could be implemented in the future to harvest this resource from the Al Saja’a Bio Refinery.

A new emerging possibility is the production of technicity polymers from sludge that can be used as fertilizer coating, fire retardant or cosmetics. The technology is not yet proven but Qatra is following one specific technology that has a great potential and envisage to deploy a pilot to demonstrate its feasibility.

A new emerging possibility is the production of technicity polymers from sludge that can be used as fertilizer coating, fire retardant or cosmetics. The technology is not yet proven but Qatra is following one specific technology that has a great potential and envisage to deploy a pilot to demonstrate its feasibility.

©2020 – Qatra

Website by ISM Media